80% less time to assemble misting lines with stainless steel pipes

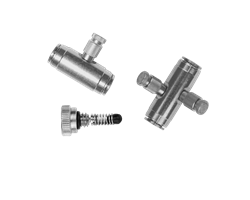

With the new Slip Lock by Club del Misting today you can assemble two stainless steel pipes with a simple click. Thanks to this new Slip Lock connection system, you will need 80% less time of the assembly time if compared to the traditional system with compression fittings.

This is not the only benefit of this system: using an AISI 303 stainless steel nozzle, you will save 30% if compared to the cost of the brass model, and you will have 100bar working pressure.

This saving may be explained considering that the stainless steel AISI 303 nozzle is a nozzle without body (unlike the traditional brass model), composed by the head and the anti-drip system that are placed just on the adapter.

With the traditional assembling system with compression fittings and brass nozzles it was necessary a long sequence of operations, involving the use of various tools, and to fix the fitting with the wrench and to assemble the adapter with Loctite®, before finally fixing the nozzle into the pipe.

With the new Slip Lock system and Stainless Steel pipes, you will use the anti-seizing spray and the pincers to couple the slip lock to the downhole lock, while the O-ring allows the hydraulic packing between pipe and fitting.

In this way, you will have a single body with Slip Lock and stainless steel tube.

For example, using the new Slip Lock system you can install a line of 60 meters with 3 meter bars in just 5 minutes, instead of the 35-minute required with the traditional system with compression fittings.

.png)

.png)

_-1549260988.jpg)